Optical Fibre Diameter Analyser: A Key Tool for Precision in Fibre Optic Cable Manufacturing

Optical Fibre Diameter Analyser: A Key Tool for Precision in Fibre Optic Cable Manufacturing

Blog Article

Just How an Optical Fibre Diameter Analyser Improves Quality Assurance in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre manufacturing processes represents a substantial development in top quality control techniques. By providing real-time, specific measurements of Fibre diameters, this innovation deals with the essential need for uniformity in production standards.

Significance of Fibre Diameter Measurement

Accurate measurement of Fibre Diameter is crucial in the field of optical Fibre innovation, as it directly influences the efficiency and dependability of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying ability, attenuation, and overall transmission efficiency. Accuracy in determining Fibre Diameter ensures that the optical residential or commercial properties are maintained within defined tolerances, which is vital for ideal signal honesty.

Variants in Fibre Diameter can bring about boosted losses due to spreading and modal dispersion, affecting the quality of information transmission. In high-speed communication systems, such disparities can cause significant degradation of signal top quality, causing information errors and minimized performance. Constant Fibre Diameter is vital for compatibility with adapters and splicing technologies, which are important parts of Fibre optic networks.

Quality control procedures in Fibre manufacturing greatly rely upon exact Diameter dimensions to make sure conformity with sector standards. By implementing robust dimension techniques, makers can enhance item reliability, reduce waste, and enhance overall system efficiency. Thus, the value of Fibre Diameter measurement can not be overstated, as it offers as a foundation in the advancement of optical Fibre innovation and its applications in contemporary interaction networks.

Exactly How the Analyser Works

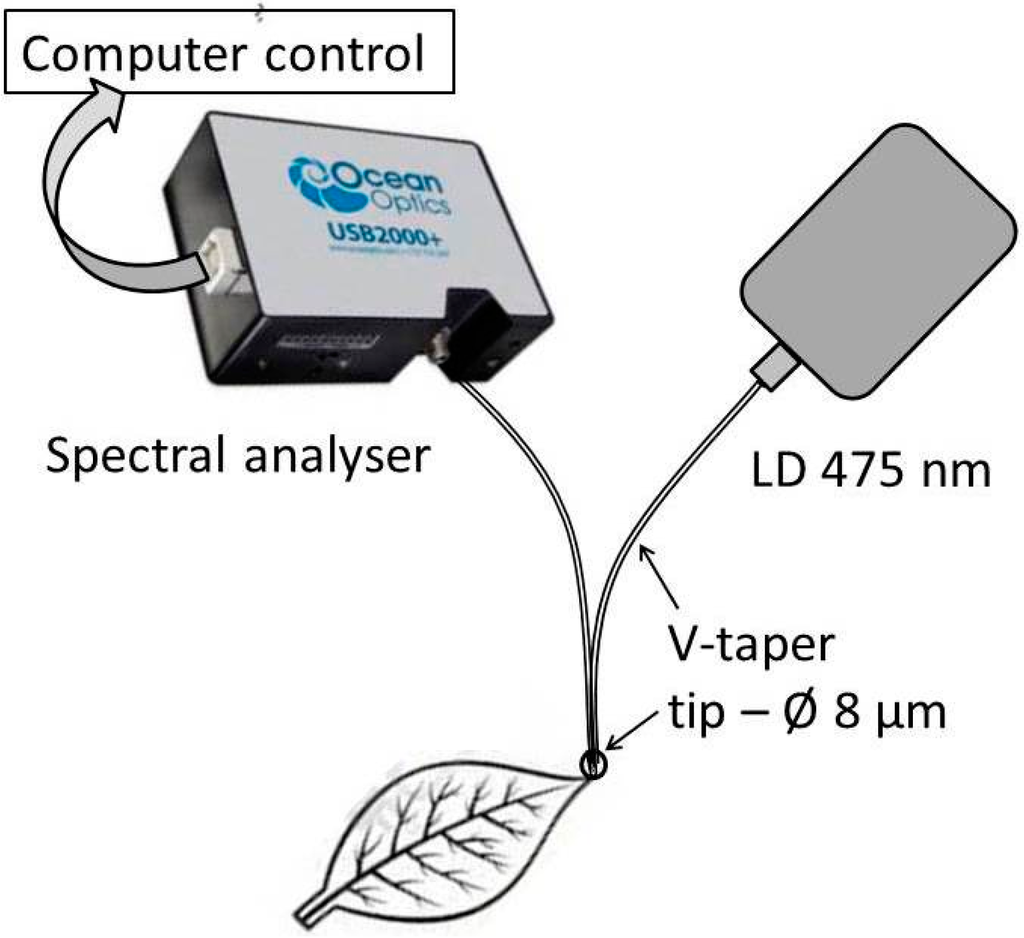

The efficient measurement of Fibre Diameter depends on innovative analytical methods that make certain precision and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a combination of laser technology and advanced image handling algorithms to properly evaluate the Diameter of fibers as they are created

At first, a laser beam of light is guided at the relocating Fibre, producing a cross-sectional shadow. The analyser records this shadow using high-resolution video cameras placed purposefully along the production line. The recorded pictures are then processed in real-time to figure out the Fibre's Diameter with outstanding accuracy.

The system uses sophisticated algorithms that make up different elements, including variations in light intensity and ecological problems, to boost measurement reliability. It can identify minute modifications in Diameter, such as changes that could happen during the production process.

In addition, the analyser can dealing with several fibres simultaneously, raising throughput without endangering accuracy. By giving rapid feedback on the Diameter, the Optical Fibre Diameter Analyser plays a critical role in maintaining strict quality assurance standards, guaranteeing that the end product meets industry specs and customer needs.

Advantages of Real-Time Surveillance

While conventional methods of keeping track of Fibre Diameter frequently entail taxing post-production checks, real-time tracking significantly boosts the effectiveness and high quality of optical Fibre production. optical fibre diameter analyser. This proactive approach permits manufacturers to identify inconsistencies in Fibre Diameter as they happen, rather than waiting till production is full to assess top quality

By continually gauging the Diameter throughout manufacturing, producers can make certain that the fibers fulfill strict specs, causing lowered variability and boosted uniformity. Real-time tracking likewise enables instant rehabilitative activities to be taken, reducing waste and preventing malfunctioning fibres from entering the supply chain.

In addition, this modern technology helps with improved information collection and analysis, giving understandings into production fads and prospective areas for renovation. Such data-driven decision-making equips suppliers to enhance procedures and preserve high standards of quality assurance.

On top of that, real-time monitoring cultivates a culture of constant improvement within the manufacturing atmosphere. Workers are much more engaged when they can see the impact of their here are the findings operate in real-time, leading to enhanced liability and a dedication to excellence. Generally, the application of real-time surveillance systems in optical Fibre manufacturing converts to remarkable product high quality and boosted customer fulfillment.

Effect on Manufacturing Efficiency

Applying optical Fibre Diameter analysers significantly boosts production effectiveness by enhancing the production procedure. These tools assist in constant tracking of Fibre Diameter, permitting producers to spot variances in real-time. By determining disparities without delay, assembly line can be adjusted quickly, minimizing downtime and reducing the likelihood of producing defective visite site items.

Additionally, the assimilation of these analysers right into the production workflow allows far better resource allowance. With accurate Diameter dimensions, drivers can optimize product use, making sure that sources are not thrown away on problematic fibres. This accuracy additionally adds to less junk and remodel, inevitably reducing production costs.

The automation offered by optical Fibre Diameter analysers reduces dependence on hand-operated evaluations, which are susceptible and typically taxing to human mistake. Consequently, employees can concentrate on more calculated tasks, boosting overall performance.

Moreover, the information generated from these analysers can notify procedure improvements and assist in far better decision-making. By assessing fads in Fibre Diameter variations, producers can carry out positive steps to improve manufacturing techniques and preserve constant top quality. In recap, optical Fibre Diameter analysers play an important function in enhancing production effectiveness, resulting in better outcome and enhanced success.

Case Research Studies and Success Stories

Across numerous industries, study highlight the transformative impact of optical Fibre Diameter analysers on manufacturing procedures. One popular example is a leading telecommunications firm that faced challenges with inconsistent Fibre diameters, bring about enhanced being rejected prices. By integrating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre measurements, leading to a 30% reduction in defects and considerable price financial savings.

In addition, a research study establishment focusing on advanced materials utilized optical Fibre Diameter analysers to fine-tune their speculative procedures. The analyser's capacity to provide in-depth insights into Fibre consistency enabled the development of cutting-edge materials with improved efficiency attributes.

These success tales highlight the crucial role of optical Fibre Diameter analysers in improving quality control, improving manufacturing efficiency, and driving advancement throughout diverse markets.

Conclusion

In conclusion, the Optical Fibre Diameter Analyser plays an essential role in improving top quality control within Fibre production. As shown with numerous case research studies, the analyser shows necessary for attaining premium product quality in Fibre production.

The application of optical Fibre Diameter analysers permitted for stringent high quality control, ensuring that the generated fibres satisfied exacting sector criteria.In conclusion, the Optical Fibre Diameter Analyser plays a critical function in boosting top quality control within Fibre manufacturing.

Report this page